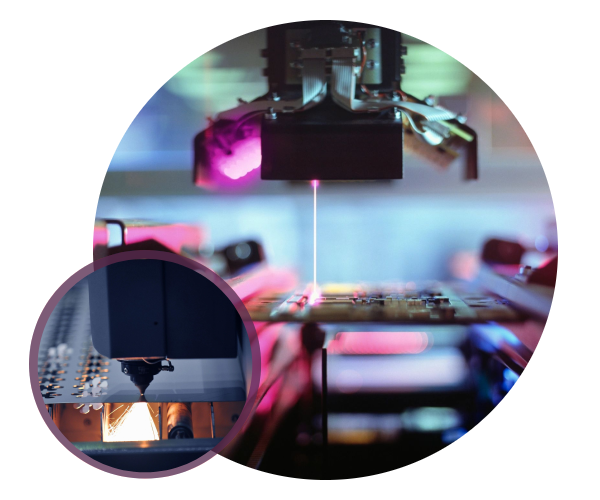

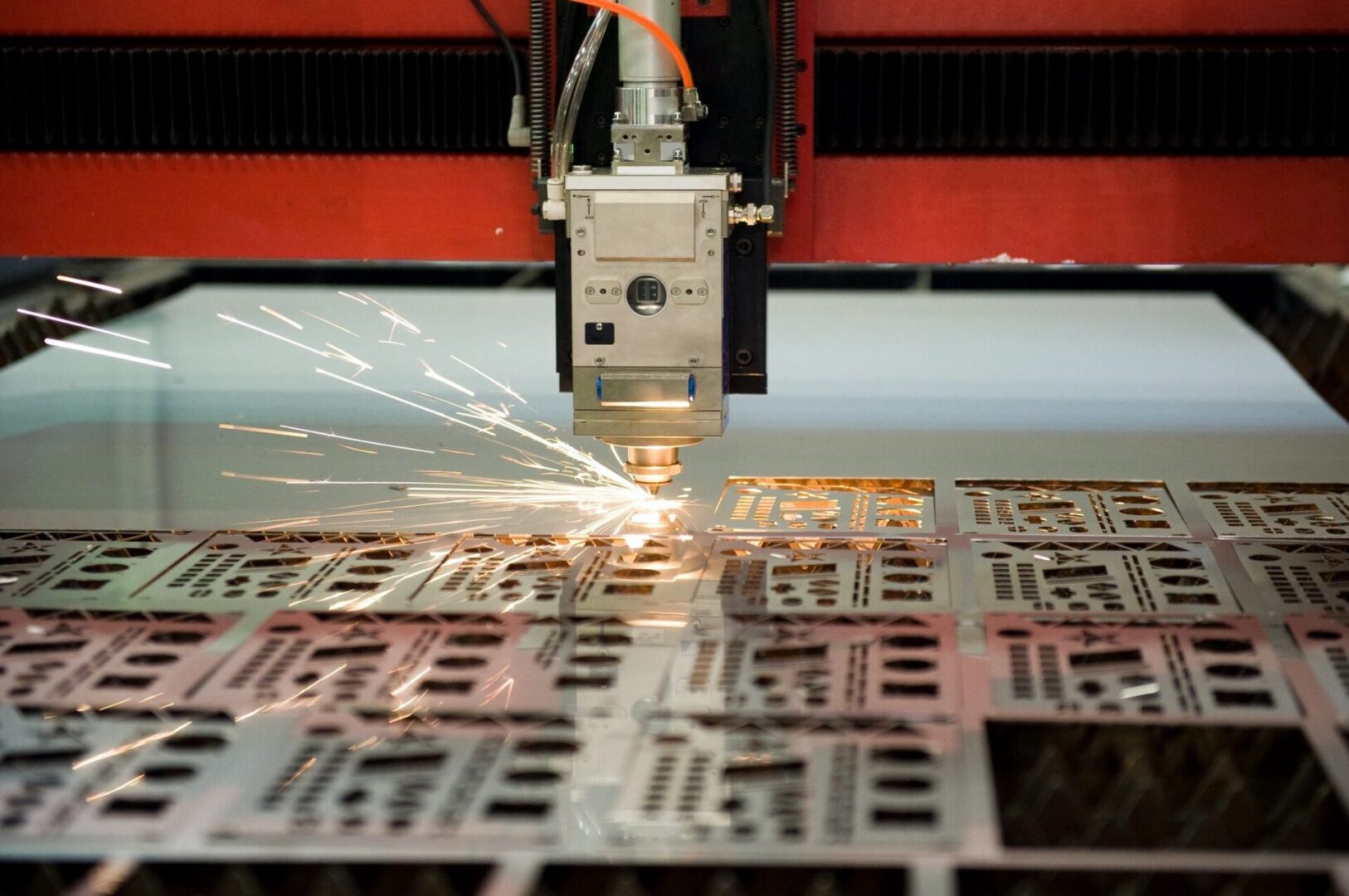

Efficient Laser-Cutting Technology for Various Products

For high-quality parts in a fraction of the time required by conventional cutting processes, North Iowa Fabrication INC. in Rockford, Iowa offers advanced laser-cutting technology. It is a quick way to produce parts because it needs little to no fixture costs.

What We Do

Our company uses state-of-the-art technology alongside the expertise of skilled fabricators to produce high-quality products with complex shapes and sizes in a small amount of time. Additionally, there are no hard tools required, so your costs and turnaround times are considerably decreased.

Laser-Cutting Services

This is ideal for fulfilling our clients’ prototyping and production needs. Any intricate parts can be cut quickly and accurately, and this technology can produce first-rate parts and fabrications in a variety of materials. With the automated load and unload system on our laser cutting equipment, North Iowa Fabrication INC. is able to reduce costs through unattended "Lights Out" laser manufacturing.

Equipment

Our team uses a versatile Mitsubishi Laser Cutting system to cut through carbon steel, stainless steel, and aluminum materials ranging in 28-gauge stock to 1-inch metal plates in thickness.

Capabilities:

Materials

Machining

North Iowa Fabrication INC.’s machining capabilities include milling, drilling, tapping, boring, and turning, just to name a few. Our equipment includes the latest in CNC vertical machining centers alongside the CNC lathe capabilities. Our CNC live tooling lathe has a bar feeder capable of running bars up to 3.00 in diameter.

Our Full-Production Machine Shop

We employ craftsmen who can handle various machine-related needs, from the initial prototype to full production. With our conventional and CNC machines, we have the knowledge and equipment needed to produce precise parts of exceptional quality, large and small.

Our Equipment

We also have multiple pieces of miscellaneous support equipment available.

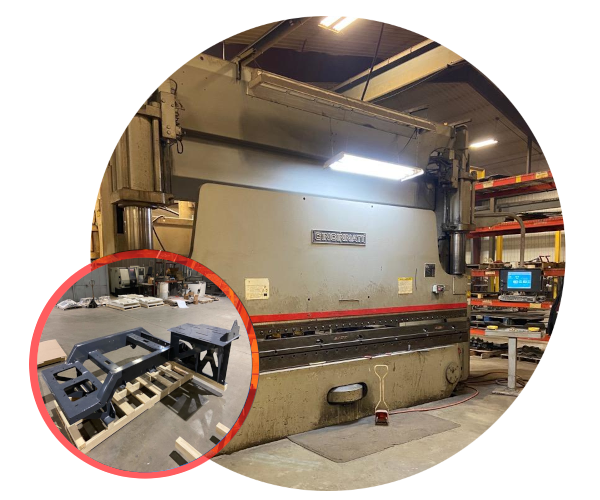

Fabrication and Forming

Parts can be efficiently processed individually in small, medium, and large lot sizes or programmed and stored for later recall. With skilled operators, every form and bend produced are precise and consistently accurate.

North Iowa Fabrication INC. has the experience, knowledge, and solutions to meet your growing requirements in forming and fabrication. With our vast array of tools, extended lead times and costs can be avoided.

Quality and Accuracy of Parts

We use a wide variety of instruments and processes to make sure the metal parts we produce are of superior quality and precise.

Turnkey Manufacturing Solutions

Our company is a highly skilled precision metal fabricator that offers complete contract manufacturing solutions. We assist customers in product development, fabrication, and manufacturing-related needs. As the experts in laser, CNC machining, and welding, we have updated facilities that house multiple machines capable of handling different operations.

Welding

North Iowa Fabrication INC. completes MIG, TIG, and spot welding in-house. This ensures our customers receive parts of the highest quality. Controlling all of the welding operations allows us to reassure our customers that they are getting products that have proper and consistent weldments that are correct every time. Additionally, our stable workforce has had many years of experience welding standard metals and specialized materials like aluminum.

Powder Coating

We have a conveyorized system that has complete pretreatment and full oven capacity. Our overhead conveyor allows us to powder coat large and small parts, which provides our customers with value-added service as a supplier of finished parts.

Comprehensive Services

Our company can fabricate parts, powder coat them, assemble, and then ship them to customers. Having this service lets us control product quality and reduce lead times. When we brought this capability in-house, we can pass along economic relief to our customers by having metal fabrication, welding, and finishing processes under one roof.